An island installation vent, at times informally called a “Chicago Circle”, “Boston circle” or “Bow Vent”, is a substitute approach to venting the snare introduced on an under-counter island sink or other comparative applications where a regular vertical vent stack or air permission valve isn’t doable or permitted. Similarly, as with all drains, ventilation should be given to permit the streaming wastewater to dislodge the sewer gas in the drain, and afterward to permit air (or another liquid) to fill the vacuum which would somehow frame as the water streams down the line. An island apparatus click here vent gives a rich answer for this need: when the drain is opened, water dislodges the sewer gas up to the sterile tee, and the water streams descend while sewer gas is uprooted vertically and toward the vent. The vent can likewise give air to fill any vacuum made. The way into a useful island installation vent is that the top elbow should be as high as the “flood level” (the pinnacle conceivable drain water level in the sink). This is to guarantee that the vent doesn’t turn into a true drain should the real drain get stopped.

Cost

The expense of establishment is high as a direct result of the number of elbows and little bits of line required. The biggest expense cost with current plastic drain pipes is work. The utilization of road elbows is useful. On the other hand, if moving the sink to an island sink, introduce the P-trap underneath the floor of the island and vent off the highest point of the drain. Connect toward the snare and opposite 180 degrees so any water in the vent streams down the drain. Incline drain down, slant vent up, and connect to existing vent from past existing apparatus that is presently deserted. Fix already existing drain to become vent.

In Canada, the public pipes code expects that the base snare arm is something like twice the line breadth, (e.g., a 1.25-inch pipe needs a 2.5-inch trap arm, 1.5 line needs a 3-inch trap arm, and so forth) and that the vent pipe is one size bigger than the drain that it serves, additionally a cleanout is expected on both the vent and the drain. The justification behind this is in case of a stopped sink, the wastewater will back up and go down the vent, potentially stopping the vent (for what it’s worth under the ledge), and a clear out would allow the cleaning of the lines.

Fitting

All DWV frameworks require different estimated fittings and lines which are estimated by the interior breadth of both the lines and the fittings which, and as a rule are plan 40 PVC wye’s, tee’s, elbows going from 90 degrees to 22.5 degrees for both inside width fitment (road) as well as external measurement fitment (center point), fix and slip couplings, minimizer couplings, and line which is normally ten feet long. All DWV framework fittings sizes depend on the measurement of the line that goes into the fittings. These are known as center fittings. Sizes for center point fittings, for example, wye’s and tee’s and crosses depend on distance across the line that goes into the center of the fittings. Things, for example, washer boxes and Studor vents are additionally estimated by the inward distance across the fittings.

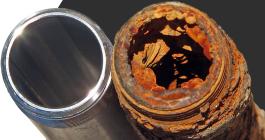

Plan 40 PVC DWV frameworks are great for a few distinct reasons and are supplanting cast iron DWV frameworks in numerous districts in the US due to issues that cast iron frameworks present. Parts are at this point not accessible for cast iron pipe fixes or establishment due to being progressively gotten rid of for lighter and more sterile materials. Since the appearance of PVC and dissolvable weld glues, which keeps the fittings intact by liquefying the material into itself, alongside the legitimate situation of help all through the DWV framework utilizing lashing and hooks as well as information on drilling openings in underlying outlining without containing the respectability, a PVC DWV framework can commonly be introduced by one individual experienced handyman rather than cast iron, which requires a few groups to introduce and eliminate.